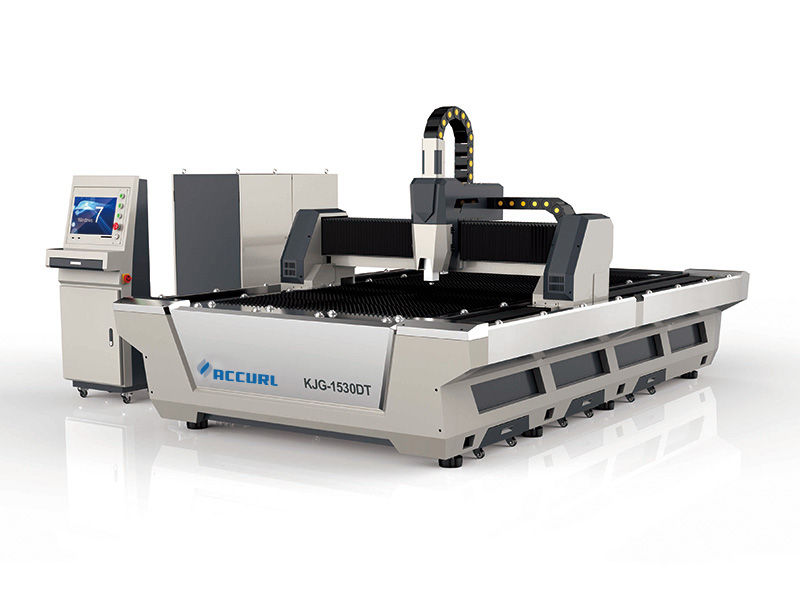

Karakteristike naše 1000watt laser machine

1.Stability and reliability of light path system and control system

2.Imported original fiber lasers,high and stable function,lifespan is over 100000 hours

3.Higher cutting quality and efficiency ,cutting speed is up to 80m/min with appearance and beautiful cutting edge

4.German high performance reducer,gear and rack;Japanese guide and ball screw.

Applicable Industry and materials of mašina za lasersko rezanje vlakana

mašina za lasersko rezanje vlakana aplikacija:

metal cutting, electrical switch manufacturing, aerospace, food machinery, textile machinery, engineering machinery, locomotive manufacturing, agriculture and forestry machinery, elevator manufacture, special vehicles, household appliances, tools, processing, IT manufacturing, oil machinery, food machinery, diamond tools, welding, welding gear, metal materials, decoration advertising, laser surface treatment of foreign processing services, such as all kinds of machinery processing industry.

Naši mašina za lasersko rezanje vlakana's Application Materials:

Professional used to cut thin sheet metal, in a variety of high quality 0.5 -3 mm carbon steel sheet cutting, can also be cutting stainless steel plate, aluminum alloy plate, galvanized sheet, electrolytic plate, silicon steel, titanium alloy, aluminium zinc plate and other metal.

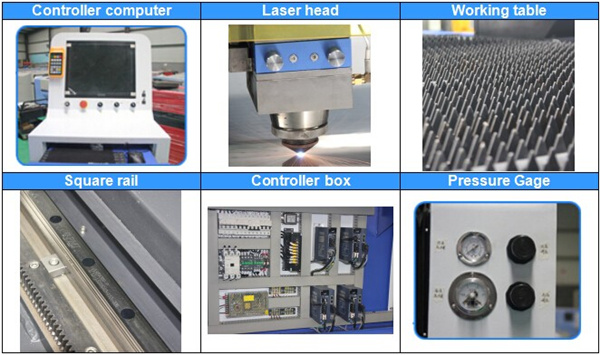

Main machine pictures of 1kw laser cutting machine

Brzi detalji

Primjena: Lasersko rezanje

Stanje: Novo

Tip lasera: Fiber laser

Primenljivi materijal: Metal

Debljina rezanja: 0-20 mm

Površina košenja: 1300 * 2500mm

Brzina rezanja: 25m/min

CNC ili ne: Da

Način hlađenja: Vodeno hlađenje

Control Software: bechoff ( Cypcut )

Podržani grafički format: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Certifikacija: CE, ISO, SGS

Dostavljena usluga: Inženjeri dostupni za servisiranje strojeva u inozemstvu

Model: 1000 watt laser

Materijali za rezanje: Etc od nehrđajućeg čelika i slično (metalna mašina za rezanje metala)

Fiber laser Generator type: Famous brand Raycus ( Made in China )

Fiber Laser cutting head: Lasermech ( From U.S. )

Motors & Drivers: 1500W Fuji servo motor made in Japan

Min. Line Width: ±0.02mm

Working life of fiber module: More than 100000 hours

Warranty time: Whole machine for 3 years (fib

Parameter of our Fiber Laser cutting Machine

| Model mašine | 2500 * 1300mm |

| Lasersko napajanje | 300W/500W/1000W/3000W |

| Fiber laser Generator type | Famous brand Raycus ( Made in China ) |

| Talasna dužina lasera | 1064nm |

Laser Beam quality | <0.373mrad |

| Working Table | Sawtooth |

| Fiber Laser cutting head | Lasermech ( From U.S. ) |

| Focus lens | Lasermech made in USA |

| Working life of fiber module | More than 100000 hours |

| Motors&Drivers | 1500W Fuji servo motor made in Japan |

| Reduktor | 3 sets from Germany |

| Guide Rails | High accuracy PMI brand from Taiwan |

| Transmit system | Dual Rack & Pinion type |

| Rack system | Germany rack |

| Chain system | Igus made in Germany |

| Water Chiller | TEYU( S&A) brand, CW6000 |

| Sistem kontrole | Professional laser control system--Cypcut

|

| Position type | Red Dot |

| Debljina sečenja | ≤3mm(stainless steel) ≤6mm(carbon steel) |

| Max. Idle Running Speed | 1400mm/s |

| Brzina sečenja | 300mm / s |

| Tačnost pozicije | ±0,05 mm/m |

| Position Speed | 20m / min |

| Min. Širina linije | ± 0.02mm |

| Power Consumption | ≤12KW |

| Carry weight | 700KG |

| voltaža | 380V/50HZ,3PH |

| Auxiliary Gas for cutting | Oxygen, Nitrogen, Air |

| Compatible software | Autocad, Coreldraw, etc |

| Graphic format | Nc |

| Working method | PC control |

| Total power protection rating | IP54 |

| Težina mašine | About 4000KG |

| Veličina mašine | 4800*2600*1800mm |

| Warranty time | Whole machine for 3 years (fiber module 2 years ) |

Quality control of 1000watt laser

Quality is our sincerest respect offered to all our customers, and it is the most important factor to maintain long-term business relationships with us.

We always pay more attention to the quality of laser cutting machine. Standard quality control system and team are responsible to insure the product quality in every process with different instruments like laser interferometer and laser power meter.

In the mechanical assemble process, the laser interferometer, laser collimator, dial indicator and marble plate are used; In the laser assemble process, the laser power meter and optical microscope are adopted.